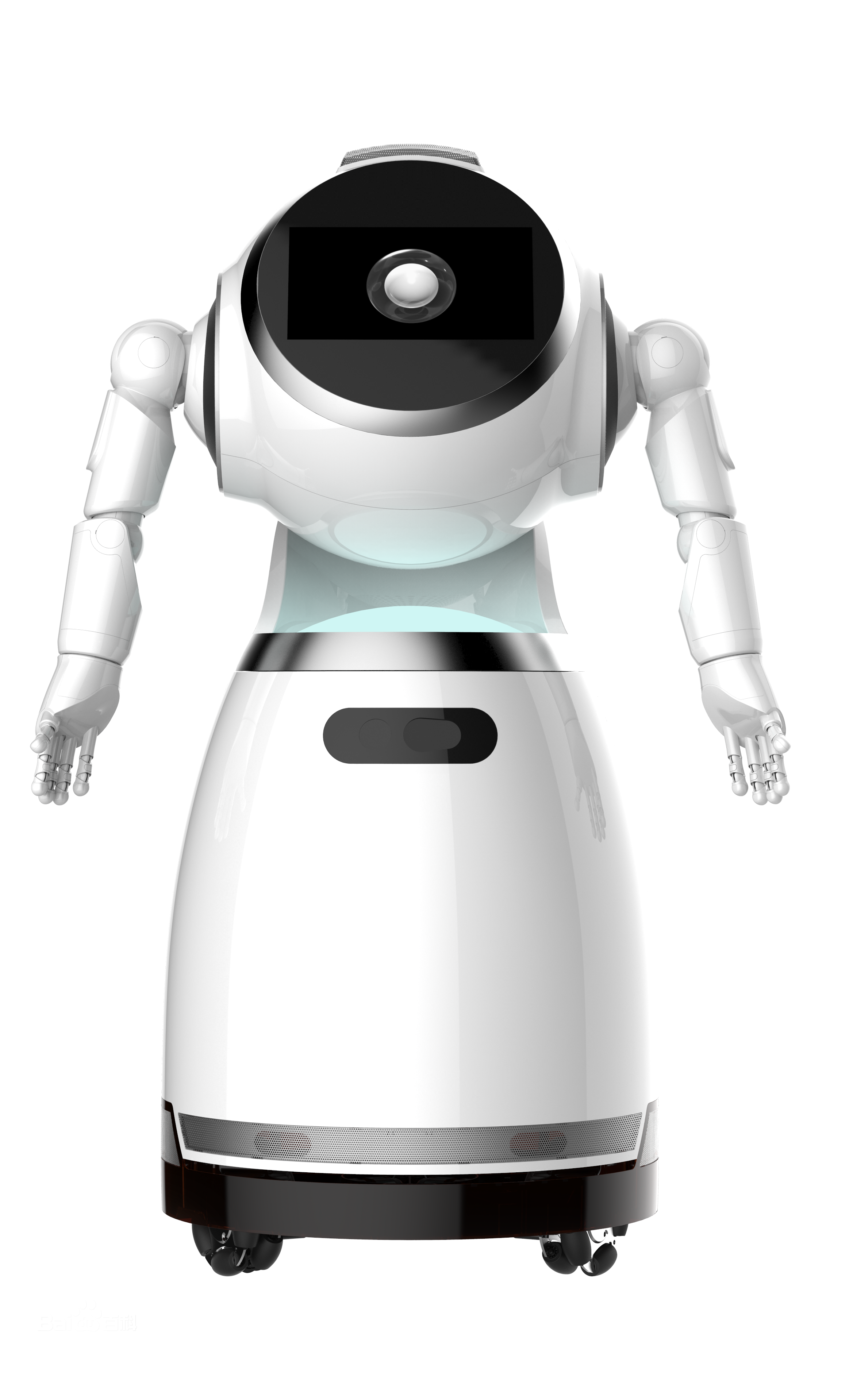

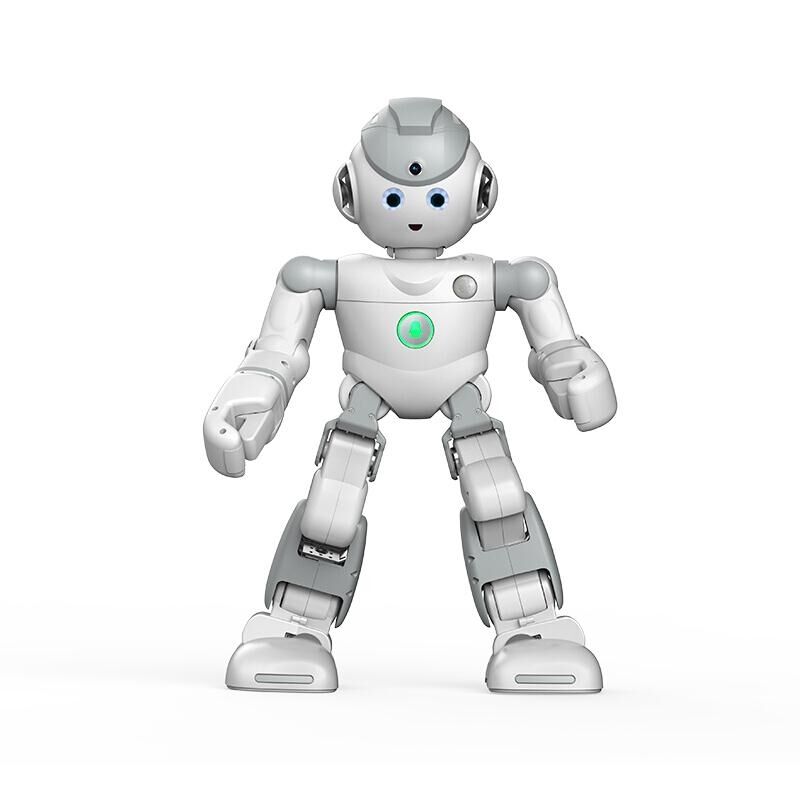

leading robots

Leading robots represent the pinnacle of modern automation technology, combining advanced artificial intelligence, precision engineering, and versatile functionality. These sophisticated machines are equipped with state-of-the-art sensors, adaptive learning capabilities, and robust mechanical systems that enable them to perform complex tasks with unprecedented accuracy. Their modular design allows for seamless integration into existing manufacturing processes, while their intuitive programming interfaces make them accessible to operators of varying skill levels. The robots feature advanced vision systems that can detect and adapt to changes in their environment, ensuring consistent performance even in dynamic conditions. Their multi-axis movement capabilities enable them to navigate complex spatial arrangements, while their precise control systems maintain optimal performance throughout extended operation periods. Safety features include emergency stop mechanisms, collision detection, and protective barriers that ensure secure operation alongside human workers. These robots excel in applications ranging from assembly line operations and material handling to quality control inspection and specialized manufacturing processes. Their ability to operate continuously with minimal downtime significantly enhances production efficiency, while their precision capabilities reduce error rates and material waste.