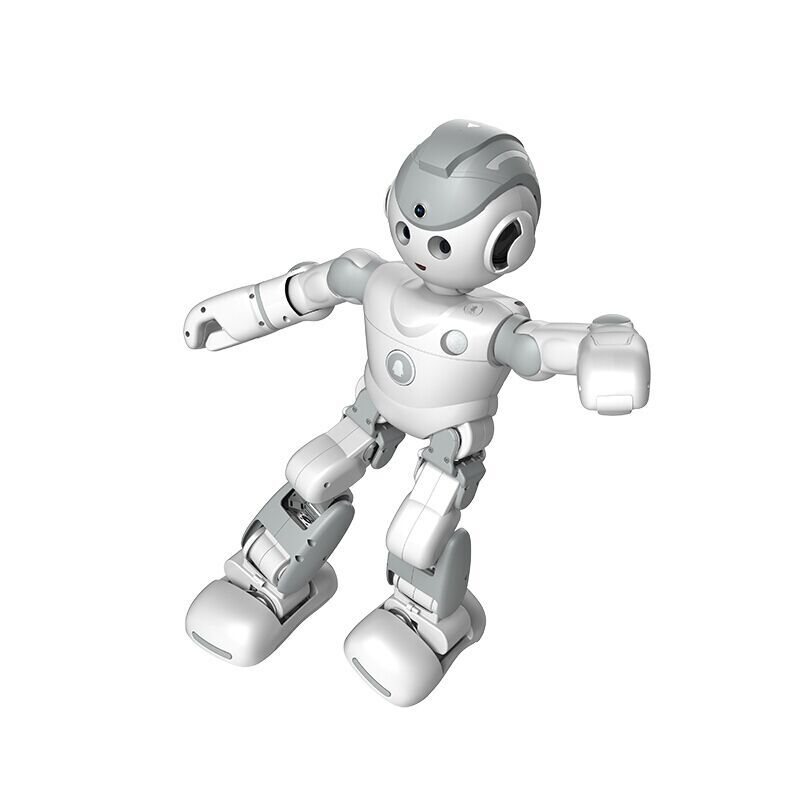

welcome robot production plant

The welcome robot production plant represents a state-of-the-art manufacturing facility dedicated to creating advanced service robots for various commercial and institutional applications. This cutting-edge facility combines automated assembly lines, quality control systems, and intelligent manufacturing processes to produce highly sophisticated welcome robots. The plant features multiple production zones, each specialized in different aspects of robot assembly, from component manufacturing to final testing. Advanced robotics and AI-driven systems ensure precise assembly and programming of welcome robots, while smart sensors and quality control mechanisms maintain consistent product standards. The facility's modular design allows for flexible production scaling, accommodating both small and large order volumes. Environmental control systems maintain optimal conditions for sensitive electronic components, while automated testing stations verify each robot's functionality before shipment. The plant incorporates Industry 4.0 principles, utilizing data analytics and IoT connectivity to optimize production efficiency and maintain quality standards. With a production capacity of up to 1,000 units monthly, the facility employs skilled technicians and engineers who oversee the manufacturing process and conduct regular maintenance and upgrades.