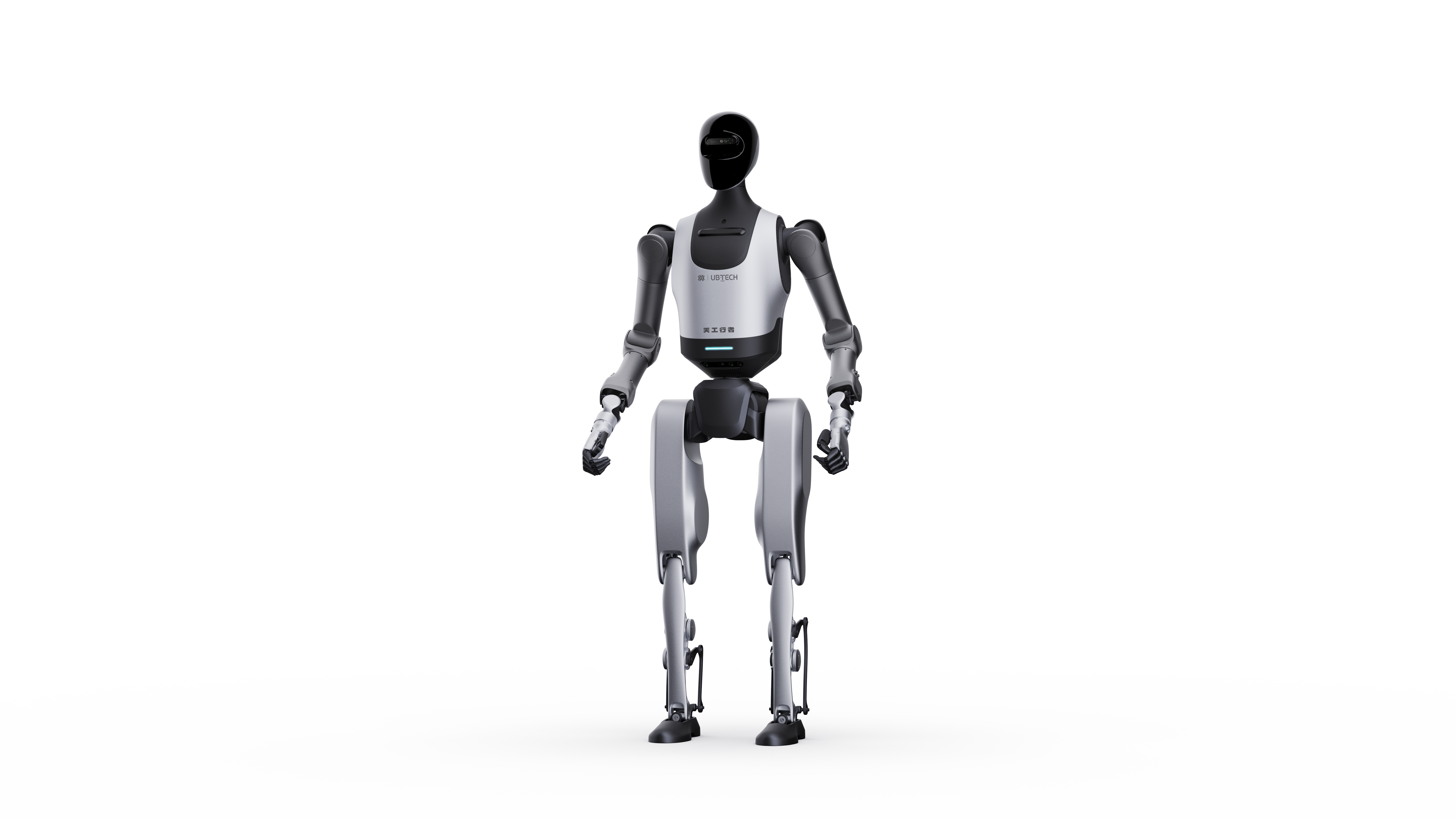

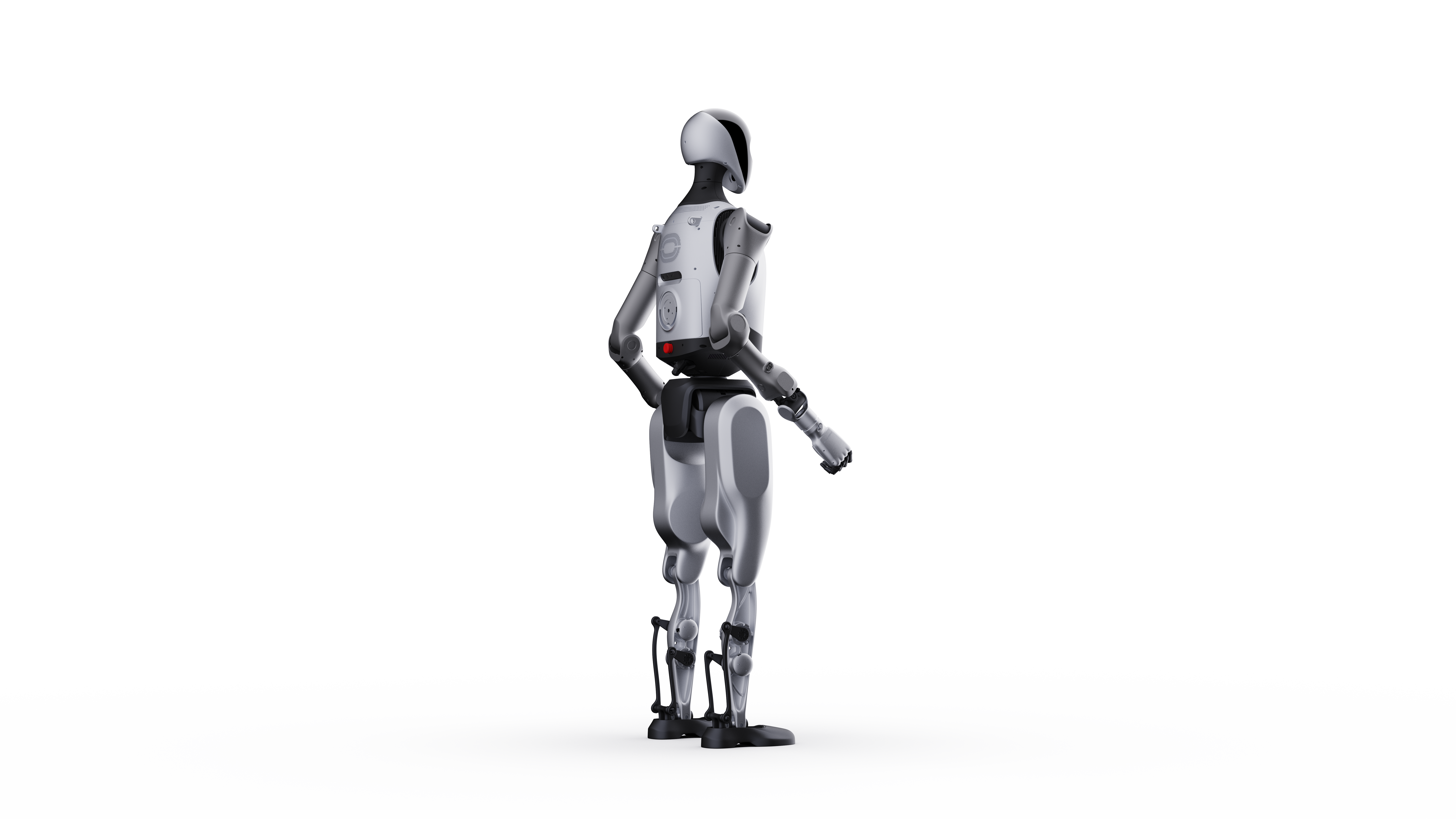

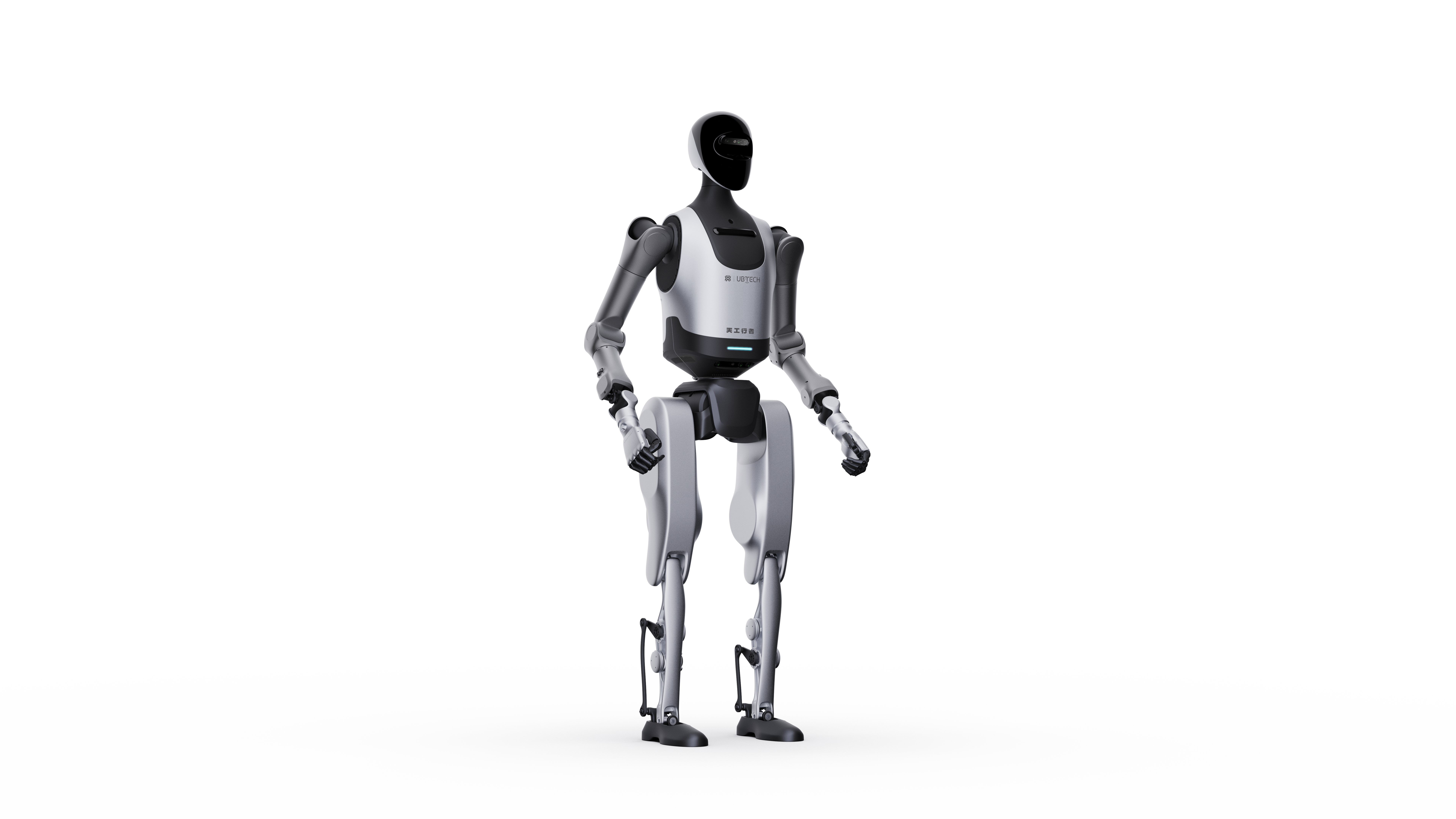

factory delivery robot

Factory delivery robots represent a cutting-edge solution in modern manufacturing logistics, combining autonomous navigation, advanced sensors, and artificial intelligence to streamline material transport within industrial facilities. These sophisticated machines are designed to efficiently move materials, components, and finished products across factory floors, warehouses, and production areas without human intervention. Equipped with state-of-the-art obstacle detection systems, these robots can navigate complex factory layouts while ensuring safety and reliability. They utilize a combination of LiDAR technology, cameras, and proximity sensors to create real-time maps of their environment and determine optimal delivery routes. The robots can operate 24/7, maintaining consistent delivery schedules and reducing operational bottlenecks. They can be seamlessly integrated with existing manufacturing execution systems and warehouse management software, enabling real-time tracking and automated task assignment. These robots feature adjustable carrying capacities, ranging from light components to heavy pallets, and can be customized with various attachment options to handle different types of loads. Their intelligent fleet management capabilities allow multiple robots to coordinate their movements, preventing traffic jams and optimizing delivery efficiency across the facility.